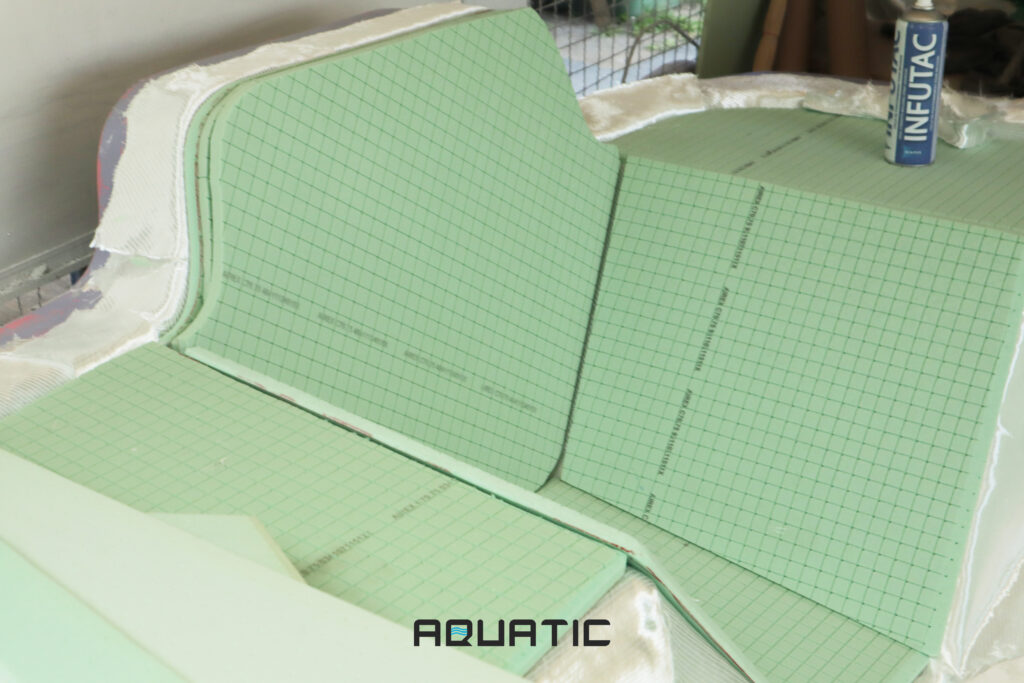

PET foam like composite material we used in our boat production not only due to their lightweight, durable, and buoyant properties. We support using of environmentally friendly material because this is a type of closed-cell foam that is made from recycled PET plastic.

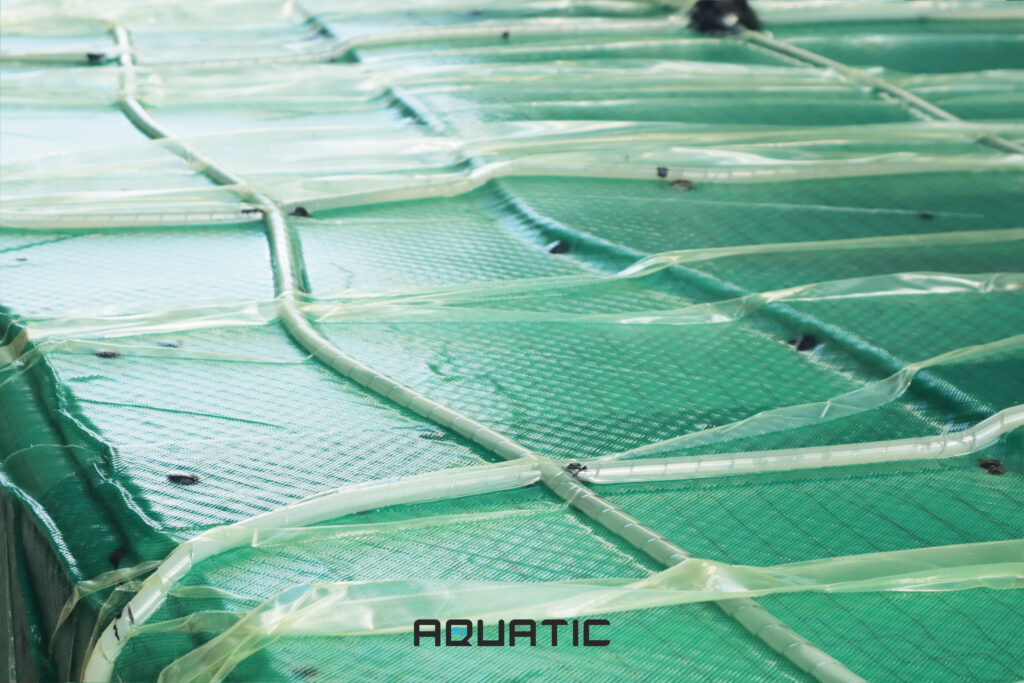

PET foam and composite materials create a strong and lightweight material that is ideal for boat production. Vacuum infusion with PET foam structure is a manufacturing process that involves infusing a composite material with resin using a vacuum.